When an offset CoG is coupled with multiple lift points, skill and experience are key.

Tweet

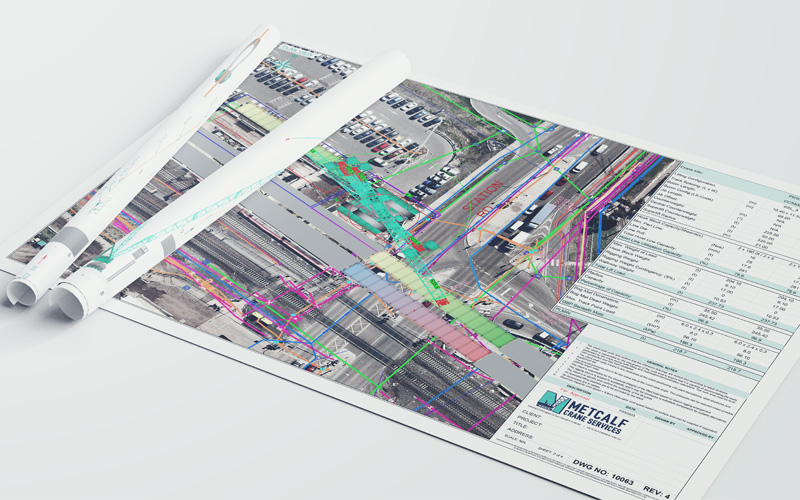

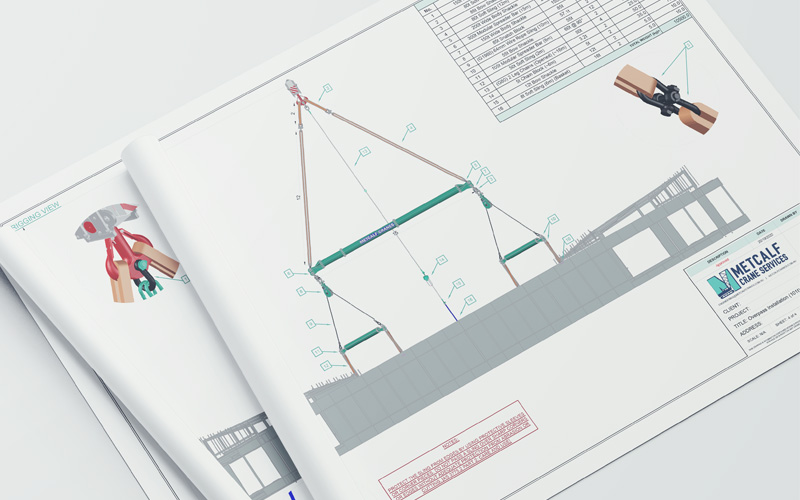

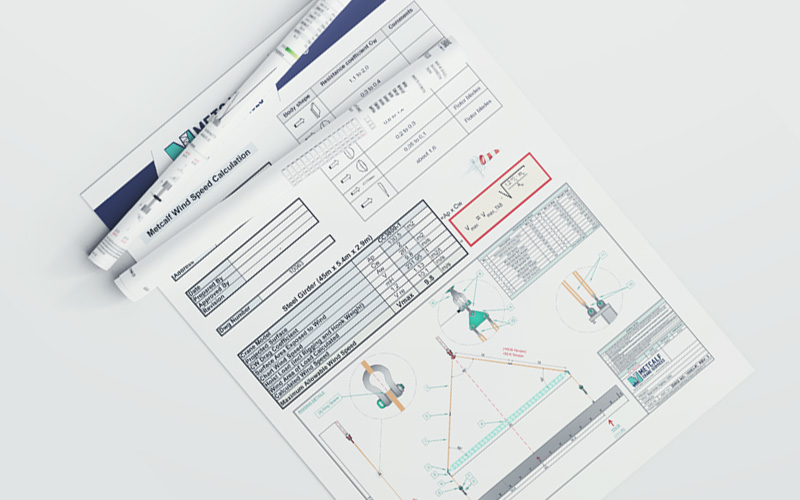

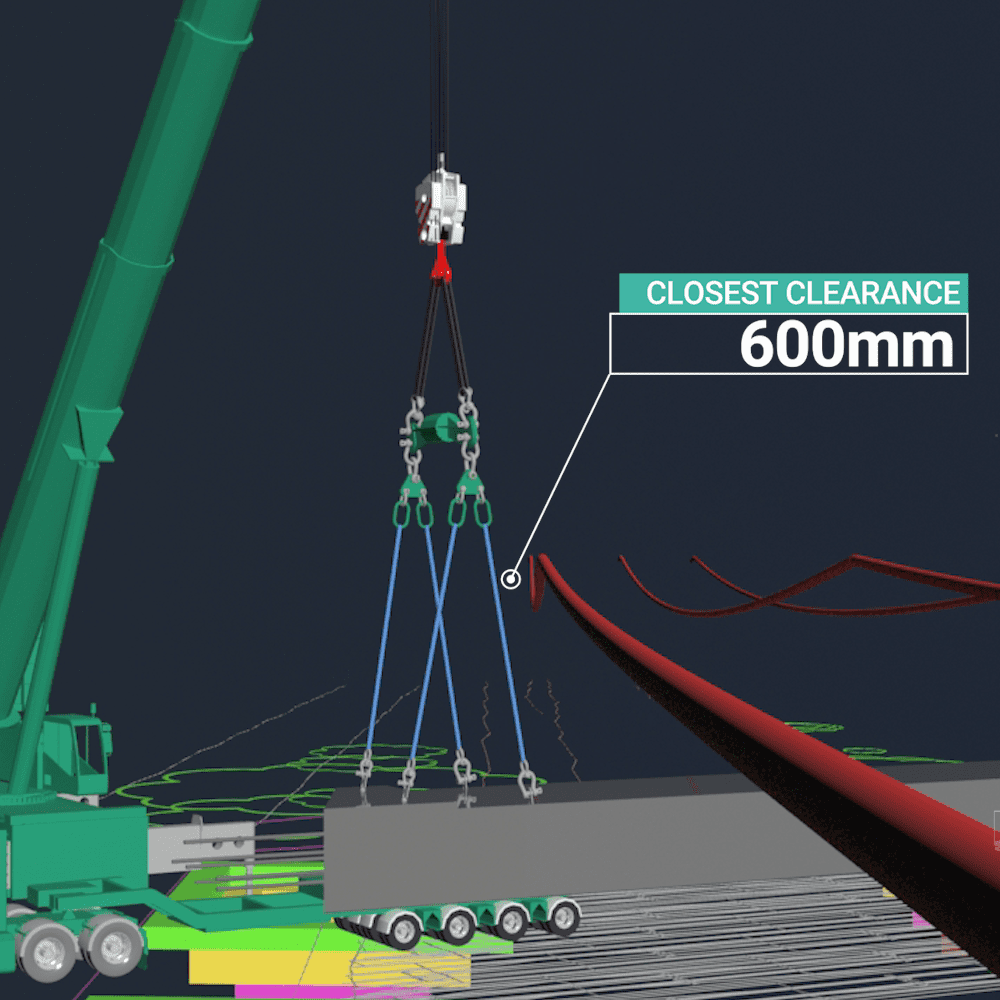

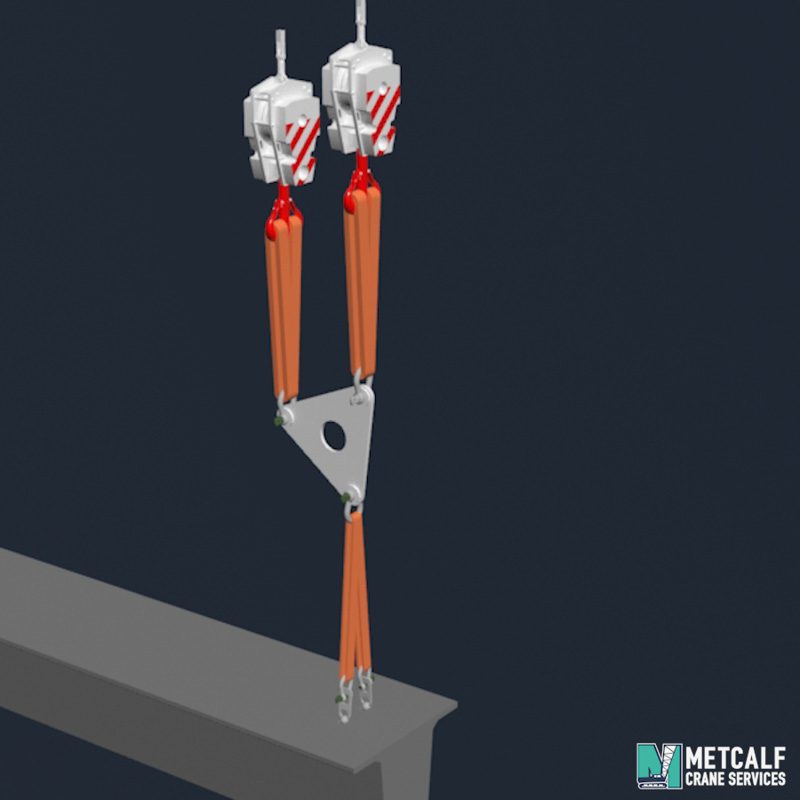

The Challenge

Safely lift a load with offset centre of gravity and multiple lift points.

The Solution

Loads with an offset centre of gravity (CoG) can prove challenging for any lifting contractor, but when an offset CoG is coupled with multiple lift points, skill

Read More

- (03) 9308 0044

- enquiries@metcalfcranes.com.au

- Mon - Fri: 7:00AM - 5:00PM